Schaarschmidt equips driverless transport systems with lithium batteries

Profile

Client:

Maschinenbau Schaarschmidt GmbH

Industry sector:

Mechanical engineering

Project:

Lithium-ion traction batteries and charging technology

Applications

For transporting up to approx. 12t

Special trough for complex AGV installation space (T-shape)

Highest safety standards

The challenge

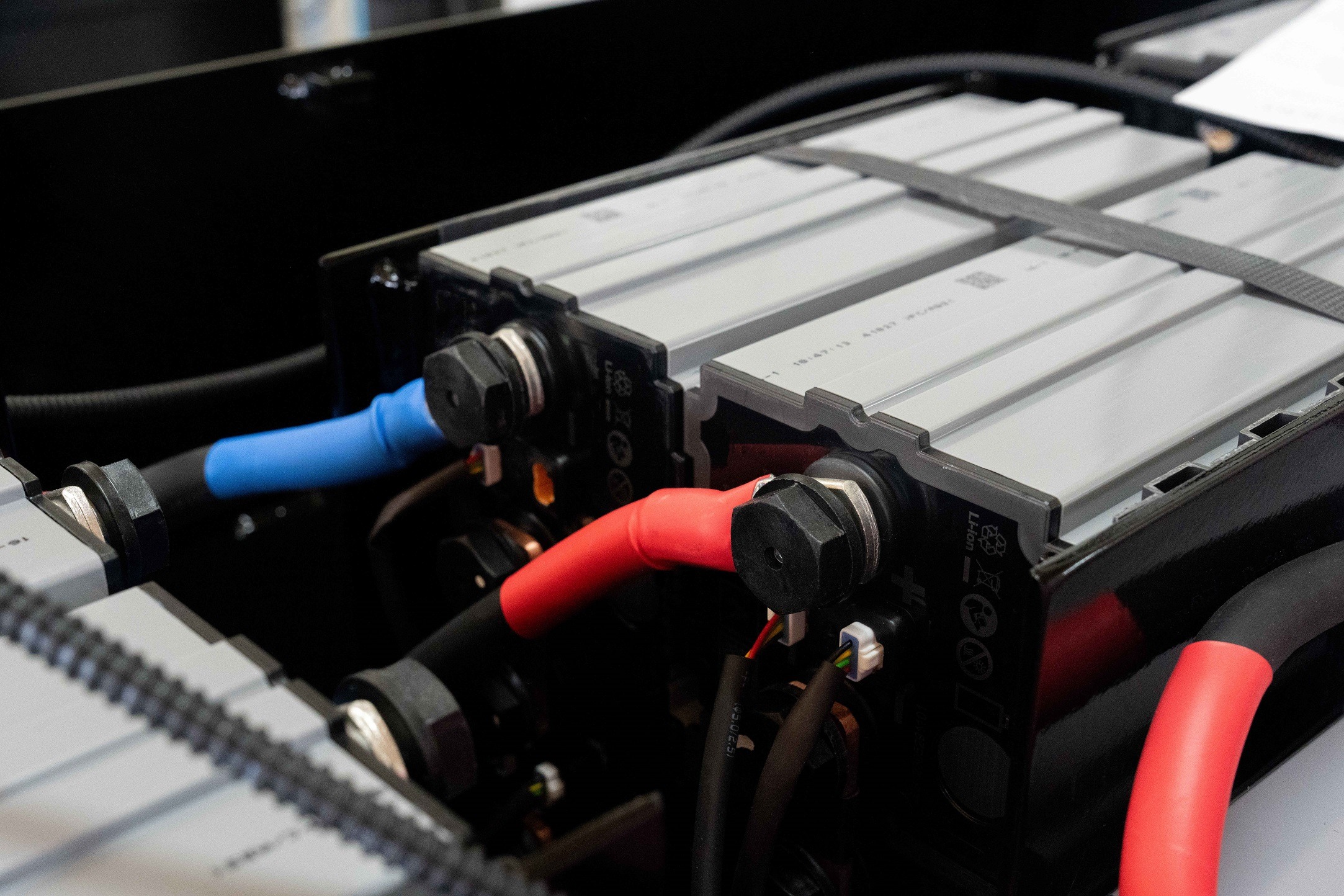

Maschinenbau Schaarschmidt GmbH, based in Gundelfingen an der Donau, is a manufacturer of special and series machines. Its product portfolio also includes AGVs (Automated Guided Vehicles), which are used in the production of Deutz AG, among others. Previously, the AGV was powered by lead-gel or lead-carbon batteries. Now it was time to switch to lithium-ion traction batteries. A particular challenge here was the complex design of the battery, as it has to be installed in a T-shape in the installation space of the AGV. The AGV at Deutz transports engine and drive trains for tractors, for example. Therefore, a battery with sufficient power was also required so that a lot of energy can be accessed at short notice.

The solution

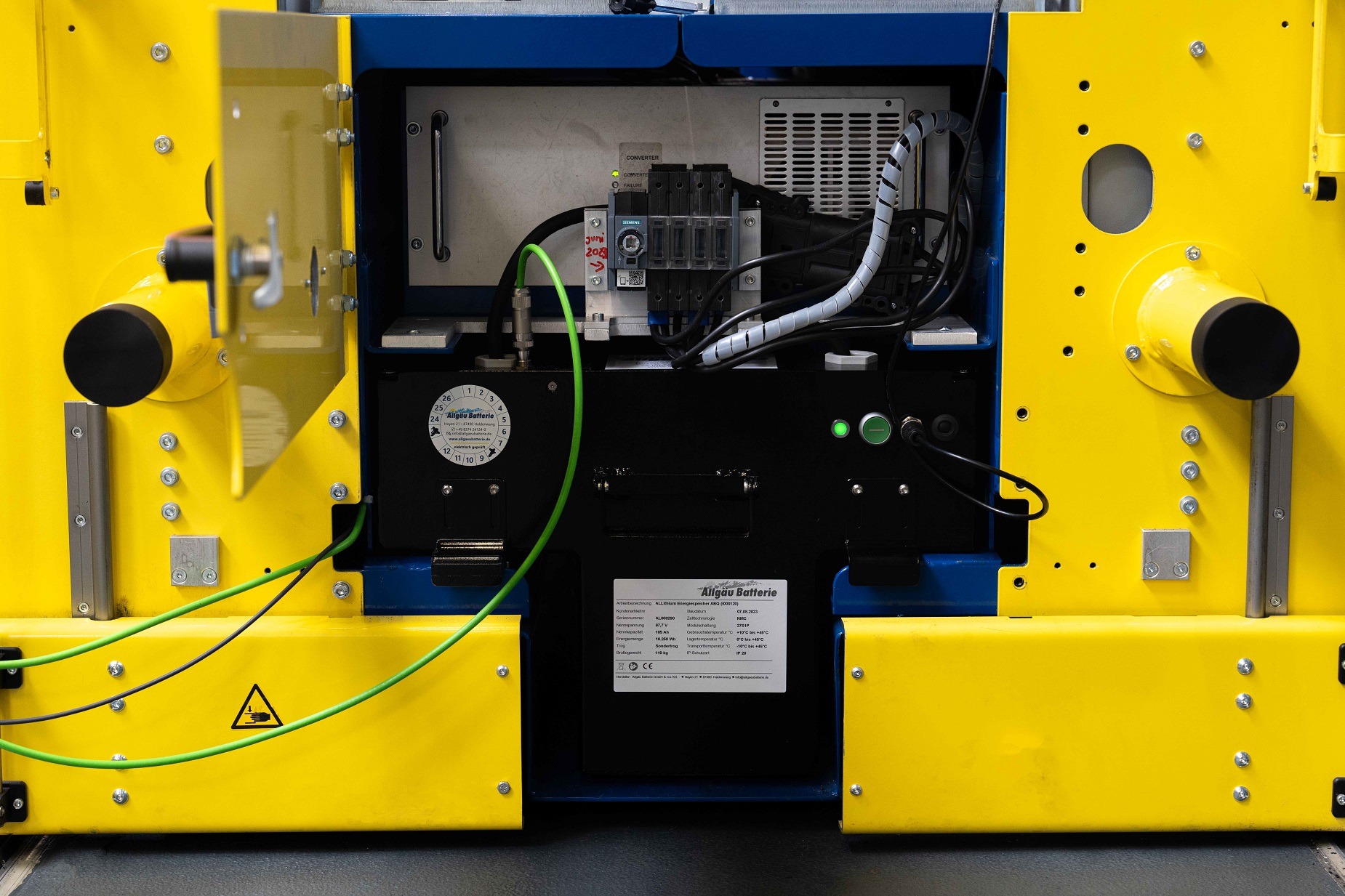

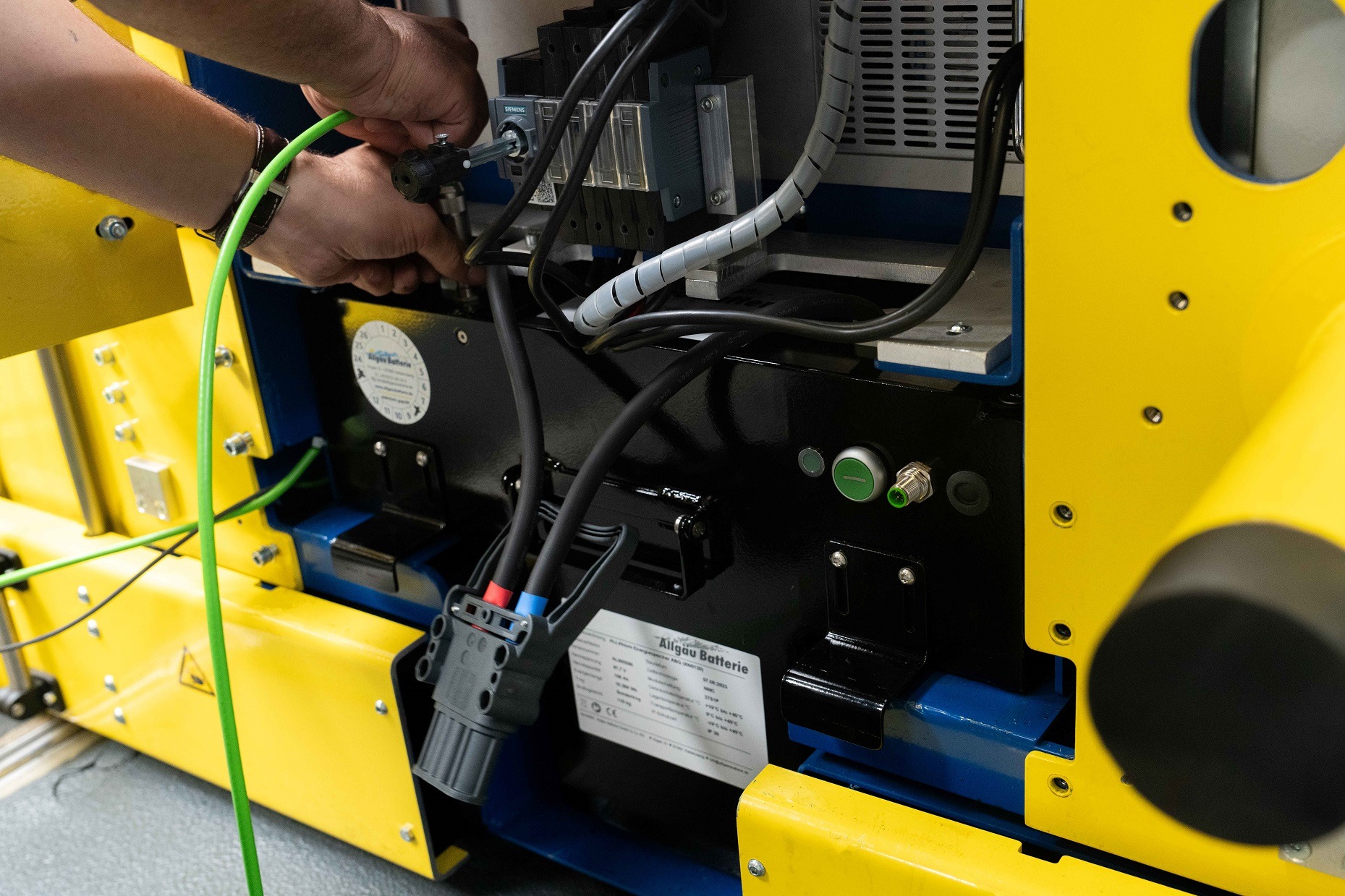

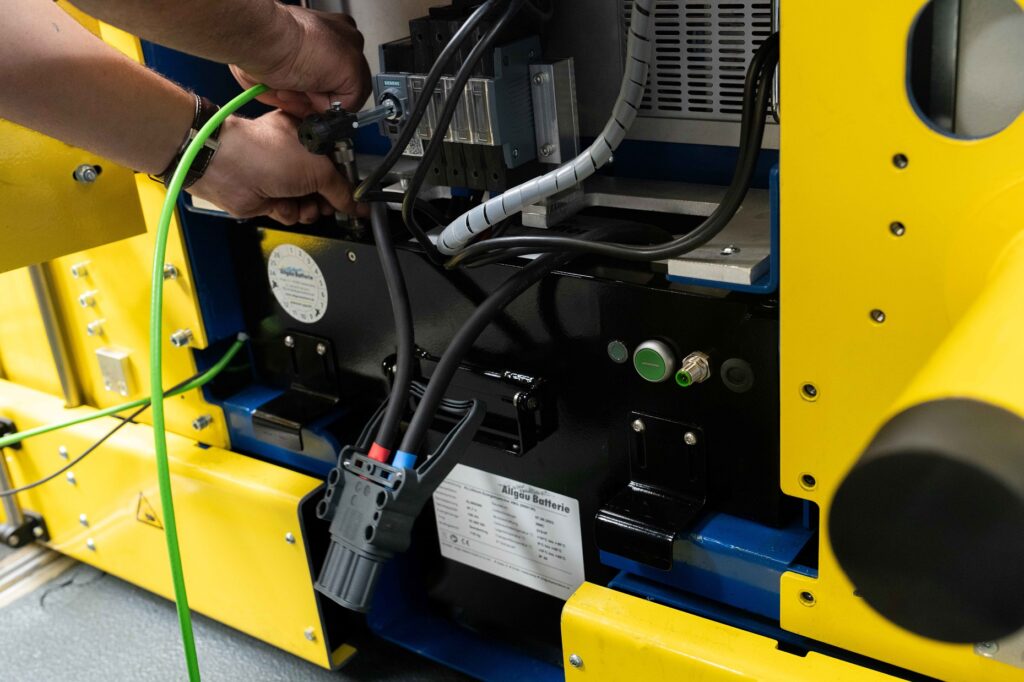

At the beginning of August 2023, Allgäu Batterie commissioned four lithium-ion traction batteries together with Maschinenbau Schaarschmidt at Deutz AG, as well as the appropriate charging technology. Each battery consists of 27 modules as well as the power electronics and the battery management system. As Allgäu Batterie manufactures the lithium-ion batteries in its own factory to customer specifications, it was also possible to create the special T-shape of the battery so that it fits perfectly into the installation space of the AGV. With a comparatively high voltage of 96 V, the energy can also be made available quickly so that Deutz AG’s production benefits from the high amount of energy released at short notice.

To enable the vehicle to communicate with the battery, a converter is installed in the battery, which provides a Profinet interface to the AGV.

Deutz AG has been a customer of Allgäu Batterie for many years in the field of lead traction batteries and charging technology. Therefore, the lithium-ion batteries were also to be supplied by Allgäu Batterie. In the future, the AGVs will be used in Deutz production in Lauingen an der Donau.

From construction to commissioning

Advantages of lithium-ion batteries

- Highest safety standards

- Lower maintenance than lead-acid batteries

- Intermediate charging capability enables AGVs to be used over the entire shift

- Intelligent battery management system for monitoring and controlling all processes in the battery

Key data

Four lithium-ion batteries

- Voltage: 96 V

- Capacity: 105 Ah

- Weight: 110 kg

ALLtrac Plus Charger

- Charging current: 24 Ah

- Voltage: 200 V

Your Contact

MAXIMILIAN BÖTSCH

Team lead

Lithium-ion-traction-batteries

Phone +49 8374 44547-42